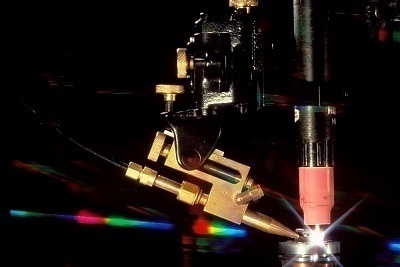

A Laser cutter is a machine that uses a laser to cut materials. The Laser Cutter works by making the laser enter through the side of the material that needs to be cut and shoots it through the axis of the beam. If a cut needs to be made and there are no edges near it, a small piercing is done before the cut. During a piercing, a high power concentrated pulse of laser beam slowly starts to make a hole, creating an edge to begin the laser cutting with.

Laser Cutter Configurations

When configuring laser cutters, there are three different configurations to choose from: moving material, hybrid, and the flying optics system. The difference among these three configurations is in the way that the laser beam moves above the material that is being cut. One common similarity that all of them do share though is that they all utilize the X and Y axis as the axis of motion, while the controller above is designated as the Z axis.

Moving materials configuration is when the material that is to be cut is stationed below a cutter head. The biggest strength about this configuration is consistency. As the laser is uniformly and steadily held above, the material can be cut quite steadily. The downside of this is that the material that is being cut (the workpiece) needs space to move around to be cut.

Hybrid lasers work because of a cooperative work between the laser header above and the workpiece below. The table moves in one axis (often the X axis) while the cutter head moves in the opposite axis (usually the Y axis). This coalition allows a relatively good and stable constant beam delivery path length than other configurations like the flying optic configuration, while also having a simpler beam delivery system.

The flying optic configuration has a moving cutter head with a stationary workpiece. This configuration usually does not require material clamping. As the moving mass is fairly consistent, the cuts are quite clean. Also, this configuration is by far the fastest among others, as its acceleration and peak velocities are superior compared to the moving materials and the hybrid systems. When changing the length of the beam from near field to the far field, techniques such as collimation, adaptive optics, or constant beam length axis is used.

These processes are for the X Y systems, but the configurations are constant for machines with more than two axis, such as the five or six axis machines, which allows formed workpieces to be cut.

derpderp

I finally understand the flying optic I figured it out from the picture on page 11 of http://www.rabbitlaserusa.com/Manuals/BeamAlignment_FlyingOptics.pdf

Mirror 1 is located at the laser tube output, mirror 2 is located on the moving x axis part. It’s actually on the rail, then mirror 3 is in the optics that move closer and further away from mirror 2 on the X axis. So mirrors 2 and 3 move up and down the Y axis on the same rail.

lachlan

Thank you for the help. This will help me during life if I ever use a lazer cutter. 🙂 😀

Hermetic Laser Sealing

Good article keep it I like this post thanks