Plasma gasification is a new garbage disposal solution using plasma technology. This garbage disposal process is self-sustaining and converts garbage into electricity. Although plasma technology has been around for years, its application to garbage disposal was never seriously considered because the conventional approach of using landfills was less expensive (even with tipping fees and transportation costs). It was only recently, with landfills in scarce supply and fuel costs constantly rising, that the plasma gasification process has merited deeper consideration.

Plasma Technology

The basics of plasma technology are straightforward. A high voltage current is passed between two electrodes to create a high intensity arc, which in turn rips electrons from the air and converts the gas into plasma or a field of intense and radiant energy.

This is the process behind fluorescent and neon lighting, where low voltage electricity passing between electrodes in a sealed glass tube containing an inert gas excites the electrons in the gas. The gas releases radiant energy and electric arc welding or cutting. This electricity passing between electrodes creates plasma that can melt metal.

Plasma Gasification

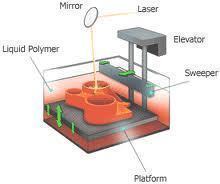

First, garbage is fed into an auger, a machine that shreds it into smaller pieces. These are then fed into a plasma chamber – a sealed, stainless steel vessel filled with either nitrogen or air. A 650-volt electrical current is passed between two electrodes. This rips electrons from the air and creates plasma.

A constant flow of electricity through the plasma maintains a field of extremely intense energy powerful enough to disintegrate the shredded garbage into its component elements. The byproduct is a glass-like substance used as raw material for high-strength asphalt or household tiles and “syngas.”

Syngas is a mixture of hydrogen and carbon monoxide and it can be converted into fuels such as hydrogen, natural gas, or ethanol. Syngas (which leaves the converter at a temperature of around 2,200 degrees Fahrenheit) is fed into a cooling system that generates steam. This steam drives turbines that produce electricity, part of which is used to power the converter, while the rest can be used for the plant’s heating/electrical needs or sold back to the utility grid.

Therefore, aside from the initial power supply from the community’s electrical grid, the whole machine can produce the electricity it needs for operations. It also produces materials that can be sold for commercial use so, at some point, the plasma gasification system will generate profit for its users.

Current and Future Applications

The system’s benefits are evident. It is self-sustaining after the initial electrical charge is used, it is environmentally friendly, and it produces materials that have commercial applications or uses and can therefore generate profit.

Aside from disposing of newly produced garbage, the system can also be used to dispose of accumulated landfill garbage so land reclamation is entirely possible. Another application planned is using the syngas as a base for producing hydrogen in commercial quantities, which will be used as fuel for hydrogen-powered vehicles.

joyce

good day!

what’s the differences between gasification and pyrolysis?

Ķirbis

Hello! Gasification is heating in presence of limited air, but pyrolysis is heating without presence of the air.

Corvel Trinchera

1. Can the plasma gasifier handle wet garbage, industrial waste and hospital waste?

2. How much will a whole system cost, from the plasma gasifier system to the genset? Can the cost be expressed in US$/ton of waste and US$/kW?

3. How much space is needed for the entire system in square meter/ton of waste?

4. Is there a distance requirement (vacant space) between the gasifier/power plant facility and the nearest residential/commercial/industrial building considering the heat generated by the plant and the risk of explosion of the syngas facility?

Thank you very much for your attention

Vern Nielsen

1. Yes, yes, and yes. Wet garbage is dried before it enters the gasifier, either from exhaust gases (co-generation or from the gasification) or by pre-heating using electricity derived from the overall process.

2. Yes and yes, but I don’t have the figures handy. If you look up “Plasco” and “Ottawa Ontario”, there are some figures that have recently been reported. Even though the figures are Canadian, seeing as how the currency is pretty much on par right now should allow you to do a direct translation.

3. If you look up PAWDS from a company called PyroGenesis, you can see that some plasma gasifiers can be relatively small (i.e. used on a cruise line). I could hazard a guess, but from what I remember you could put the entire plant on a 40′ x 120′ lot… or maybe two.

4. I guess it depends on city zoning guidelines. Plasma gasifiers are used at hospitals, and I’d bet that some are located very close to residential communities.